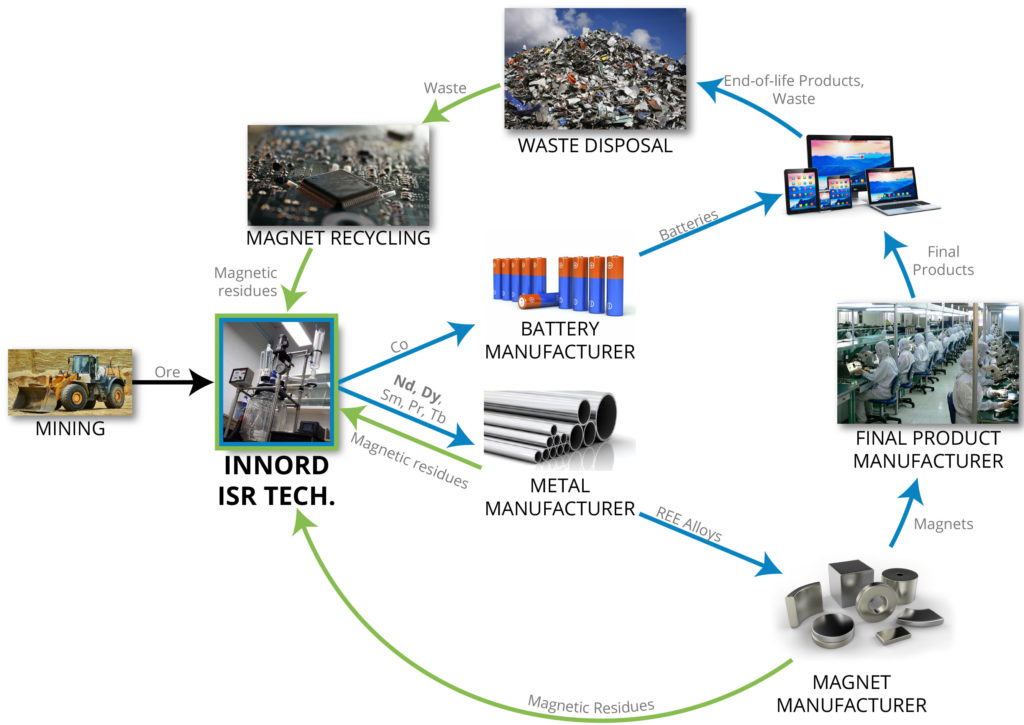

REE RECYCLING

“We are going to process 1.5 tonnes of magnet waste per day as our starting point. What is magnet waste? It comes from two sources. One is from grinding the magnet metal down from a block to a particular shape. The other is end of life material. Both streams are running at 30% rare earth elements. It doesn’t matter if I’m getting a magnet from China, the US, Canada, or wherever — it’s always going to be running at approximately 30% rare earths. And it’s not just any rare earths. It always has those four elements: NdPrDyTb. I don’t have to deal with any of the cheap elements, like lanthanum and ceriums.”

“To process 1.5 tonnes per day over eight hours, we are looking at a low capex of $2.6 million dollars. That’s our starting point. With an operating cost of $3.00 per kilogram of rare earths, we can generate $10 million dollars on a $2.6M investment with a 20% profit margin. If I drive it up to full 24 hour operation, then we can process 4.5 tonnes per day. Do the math and you see $30 million dollars of sales with $6-8 million of profits. All that with a $2.6 million dollar investment — that’s starting to sound very interesting.”

Problem

- Large volumes of waste from magnet manufacturers are poorly disposed of while it represents an important source of key Rare Earth Elements (REE – Nd/Pr/Dy/Tb)

- Current REE separation technology (Solvent Extraction – SX), is a process with a well-known adverse environmental impact which has been developed over the years in China and is now kept in secret.

- Secure supply of REE outside of China is required to support Clean Technologies (Energy, Energy storage and Sustainable mobility)

Our Technology (ISR)

- Use magnet residue and recycled magnets as main source of feed with key REE (Nd/Dy)

- Magnet residue from magnet manufacturers ideal feed (scraps & swarf)

- End-of-life-permanent magnet recycling is growing every year

- ISR uses organic-solvent-free and feasible technology to isolate and purify REE

- Feed from magnet manufacturers, alloy makers and recyclers across Europe and US to be processed in Canada